Carbide Tools Market Overview

The global carbide tools market has been witnessing significant growth owing to the increasing demand for high-performance cutting tools across various industries such as automotive, aerospace, manufacturing, and construction. According to a detailed analysis by Expert Market Research (EMR), the global carbide tools market size was valued at USD 10.79 billion in 2023 and is expected to expand at a steady CAGR of 5.80% during the forecast period (2024-2032), reaching a projected value of USD 17.92 billion by 2032.

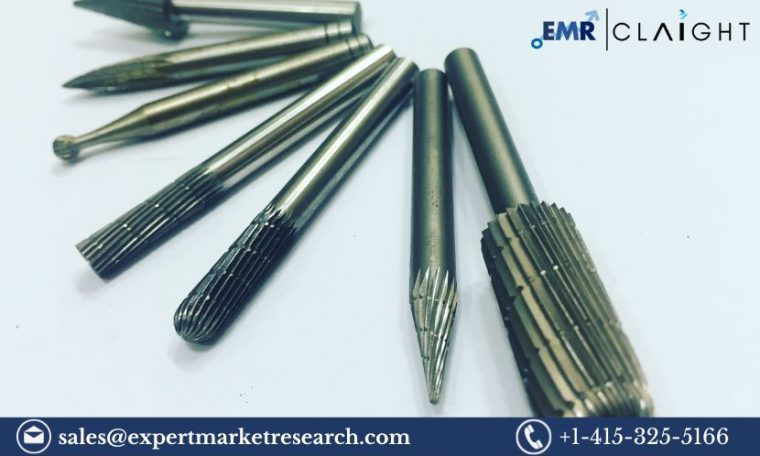

Understanding Carbide Tools

Carbide tools, also known as cemented carbide tools or tungsten carbide tools, are cutting tools made from a composite material comprising hard carbide particles (usually tungsten carbide) bonded together by a metallic binder (typically cobalt). Carbide tools are renowned for their exceptional hardness, wear resistance, and heat resistance, making them ideal for high-speed machining applications and demanding cutting operations across various materials such as metals, alloys, composites, and plastics.

Market Drivers

The global carbide tools market is driven by several key factors that are contributing to its growth trajectory. One of the primary drivers is the growing demand for precision machining and high-quality surface finishes in manufacturing industries such as automotive, aerospace, and electronics. Carbide tools offer superior performance characteristics such as high hardness, toughness, and thermal stability, enabling manufacturers to achieve tight tolerances, intricate geometries, and superior surface finishes in their products.

Furthermore, the increasing adoption of advanced manufacturing technologies such as CNC machining, additive manufacturing, and automation is driving demand for carbide tools. Carbide inserts, drills, end mills, and taps are widely used in automated machining processes to improve productivity, efficiency, and cost-effectiveness by reducing cycle times, tool changes, and scrap rates, thereby enhancing the competitiveness of manufacturing operations.

Moreover, the expanding automotive and aerospace industries, driven by factors such as urbanization, infrastructure development, and technological advancements, are fueling demand for carbide tools. Carbide cutting tools are essential for machining complex components such as engine parts, aircraft structures, and turbine blades from advanced materials such as titanium, stainless steel, and carbon fiber composites, where conventional tooling solutions may not suffice.

Carbide Tools Market Trends

The global carbide tools market is witnessing several notable trends that are reshaping industry dynamics. One prominent trend is the increasing adoption of advanced coatings and surface treatments to enhance the performance and longevity of carbide tools. Titanium nitride (TiN), titanium aluminum nitride (TiAlN), and diamond-like carbon (DLC) coatings are applied to carbide inserts and end mills to improve wear resistance, lubricity, and chip evacuation, thereby extending tool life and reducing machining costs.

Moreover, there is a growing trend towards customization and tailor-made solutions in the carbide tools market. Manufacturers are offering a wide range of carbide tool geometries, grades, and specifications tailored to specific machining applications, materials, and operating conditions. Customized carbide tooling solutions optimized for performance, productivity, and cost-effectiveness are gaining popularity among manufacturers seeking to maximize machining efficiency and competitiveness.

Additionally, the advent of Industry 4.0 technologies such as artificial intelligence (AI), machine learning, and internet of things (IoT) is driving innovation and digitalization in the carbide tools market. Smart carbide tools embedded with sensors and connectivity features enable real-time monitoring of tool wear, cutting parameters, and machine performance, facilitating predictive maintenance, process optimization, and data-driven decision-making in manufacturing operations.

Carbide Tools Market Segmentation

The market can be divided based on product type, coating type, configuration, end use, and region.

Market Breakup by Product Type

- Drilling Tools

- Milling Tools

- Turning Tools

- Others

Market Breakup by Coating Type

- Coated

- Non-coated

Market Breakup by Configuration

- Hand-based

- Machine-based

Market Breakup by End Use

- Automotive

- Construction

- Metal Fabrication

- Electronics and Electrical

- Aerospace

- Others

Market Breakup by Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Competitive Landscape

The EMR report looks into the market shares, plant turnarounds, capacities, investments, and mergers and acquisitions, among other major developments, of the leading companies operating in the global carbide tools market. Some of the major players explored in the report by Expert Market Research are as follows:

- OSG Corporation

- Sandvik AB

- Kennametal Inc

- Sumitomo Electric Industries, Limited

- Guhring, Inc

- Fullerton Tool Company, Inc

- Ingersoll Cutting Tool Company

- KYOCERA SGS Precision Tools

- Elenco Carbide Tool Corp.

- Others

Market Challenges

Despite the positive outlook, the global carbide tools market faces certain challenges that may impact its growth prospects. One of the key challenges is the volatility of raw material prices, particularly tungsten and cobalt, which are primary constituents of carbide tooling materials. Fluctuations in raw material costs and supply chain disruptions may impact production costs and profit margins for carbide tool manufacturers, necessitating strategic sourcing and supply chain management initiatives.

Additionally, competition from alternative tooling materials such as high-speed steel (HSS), ceramic, and cubic boron nitride (CBN) may pose challenges for market penetration and differentiation. While carbide tools offer superior performance characteristics in many applications, alternative materials may offer advantages in specific machining conditions or cost-sensitive applications, requiring carbide tool manufacturers to demonstrate value and provide differentiated solutions to customers.

Furthermore, technological advancements in cutting tool coatings, geometries, and substrates may drive innovation and evolution in the carbide tools market, posing challenges for incumbents to stay ahead of the curve and maintain their competitive edge. Continuous investment in research and development, product innovation, and collaboration with end-users are essential for carbide tool manufacturers to address evolving customer needs and market dynamics.