In the complex world of industrial infrastructure, the choice of components can significantly impact system performance, reliability, and longevity. Among the myriad options available, ptfe expansion bellow expansion bellows emerge as a preferred solution for engineers and project managers seeking to enhance the efficiency and flexibility of piping systems. But what exactly are the benefits of using ptfe expansion bellow and why are they increasingly favored in various industries? In this comprehensive guide, we delve into the advantages of incorporating PTFE expansion bellows into piping systems, shedding light on their significance and applications.

PTFE expansion bellows offer numerous advantages in piping systems. Their exceptional chemical resistance ensures longevity in corrosive environments, while thermal stability allows for operation in extreme temperatures. Flexible design absorbs movement and vibration, reducing stress on piping and equipment. Low friction minimizes wear and enhances efficiency. s ptfe expansion bellow makes it ideal for pharmaceutical and food industries. Versatile configurations suit diverse applications. Overall, ptfe expansion bellow bellows enhance system reliability, longevity, and performance across various industries.

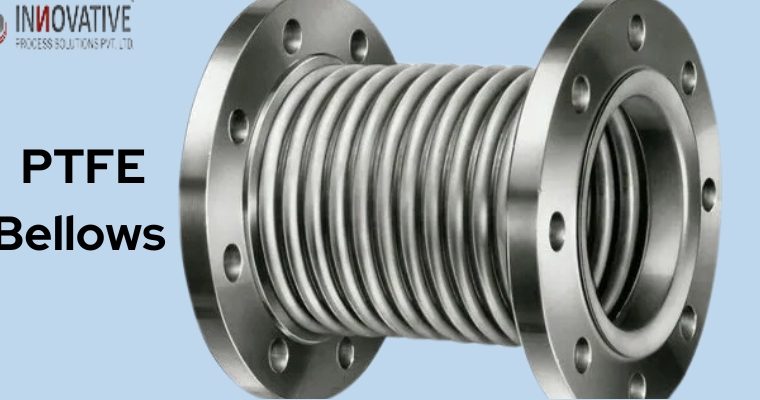

Understanding PTFE Expansion Bellows

Before delving into their benefits, let’s first grasp the fundamentals of PTFE expansion bellows. These flexible components, typically constructed from PTFE—a synthetic fluoropolymer known for its exceptional chemical resistance, thermal stability, and low friction properties—are designed to absorb thermal expansion, contraction, and mechanical vibrations within piping systems. Their convoluted folds allow for flexibility and movement, preventing stress on the piping and connected equipment.

In industrial piping systems, PTFE expansion bellows offer a multitude of benefits. First and foremost, their exceptional chemical resistance ensures durability even in corrosive environments, safeguarding against degradation and extending the lifespan of the piping system. Additionally, PTFE’s thermal stability enables these bellows to withstand extreme temperatures, maintaining flexibility and functionality across diverse operating conditions.

Their flexible design allows for the absorption of movement and vibration, reducing stress on the piping and associated equipment, thereby minimizing the risk of damage and prolonging service life. Furthermore, PTFE’s low friction properties contribute to enhanced efficiency and reduced energy consumption within the system. Overall, the utilization of PTFE expansion bellows results in improved reliability, longevity, and performance, making them indispensable components in industrial piping applications.

The Advantages of PTFE Expansion Bellows

- Chemical Resistance: One of the primary benefits of PTFE expansion bellows is their exceptional resistance to a wide range of chemicals and corrosive substances. PTFE’s inert nature makes it impervious to most corrosive fluids, acids, and solvents, ensuring the integrity and longevity of the expansion bellows even in aggressive environments.

- Temperature Stability: PTFE is renowned for its ability to withstand extreme temperatures, ranging from cryogenic levels to high heat environments. As a result, PTFE expansion bellows maintain their flexibility and performance across a wide temperature range, making them suitable for applications in both cold and hot process piping systems.

- Flexibility and Movement Absorption: PTFE expansion bellows excel at accommodating thermal expansion, contraction, and mechanical vibrations within piping systems. Their flexible design allows them to extend and compress in response to system movements, preventing stress on the piping and connected equipment. This flexibility minimizes the risk of damage and fatigue failure, thereby prolonging the lifespan of the piping system.

- Reduced Friction and Wear: PTFE’s low coefficient of friction contributes to reduced wear and tear on the expansion bellows during operation. This property not only enhances the longevity of the bellows but also reduces frictional losses in the piping system, resulting in improved efficiency and energy savings over time.

- Vibration Damping: PTFE expansion bellows act as effective vibration isolators, dampening mechanical vibrations generated by pumps, compressors, and other equipment. By absorbing these vibrations, the expansion bellows prevent their transmission to the rest of the piping system, reducing noise and minimizing the risk of equipment damage or failure.

- Versatility and Adaptability: PTFE expansion bellows are highly versatile components that can be customized to suit the specific requirements of different piping systems. They are available in various sizes, configurations, and end connections, allowing for seamless integration into a wide range of applications across diverse.

Applications Across Industries

The benefits of using PTFE expansion bellows extend across a multitude of industries:

- Chemical Processing: In chemical plants and refineries, where exposure to corrosive chemicals is common, PTFE expansion bellows are used to accommodate thermal expansion and contraction in piping systems while resisting chemical attack.

- Power Generation: Power plants utilize PTFE expansion bellows in steam lines, boiler feedwater systems, and cooling water circuits to absorb movements and vibrations, ensuring the reliability and efficiency of the equipment.

- Petrochemicals: In petrochemical facilities, PTFE expansion bellows are employed in pipelines transporting volatile hydrocarbons and other fluids, where flexibility and durability are essential for maintaining system integrity.

- Pharmaceuticals: The inert nature of PTFE makes it ideal for pharmaceutical applications, where cleanliness and product integrity are paramount. PTFE expansion bellows accommodate thermal expansion and contraction while maintaining hygienic standards in fluid handling systems.

- Food and Beverage: In food processing plants, PTFE expansion bellows are used to accommodate thermal expansion and contraction in sanitary piping systems, ensuring compliance with strict hygiene standards while enhancing system flexibility and reliability.

Considerations for Implementation

When considering the use of PTFE expansion bellows in piping systems, several factors should be taken into account:

- Operating Conditions: Evaluate the temperature range, pressure ratings, and chemical compatibility requirements of the application to ensure that the expansion bellows are suitable for the intended environment.

- System Design: Consider the layout, flow requirements, and potential movement scenarios within the piping system to determine the appropriate size, configuration, and placement of the expansion bellows.

- Quality and Reliability: Choose expansion bellows from reputable manufacturers known for their quality craftsmanship and adherence to industry standards. High-quality bellows minimize the risk of premature failure and ensure long-term performance.

- Installation and Maintenance: Proper installation and regular maintenance are crucial for maximizing the lifespan and performance of PTFE expansion bellows. Follow.

PTFE expansion bellows offer significant advantages in piping systems. Their exceptional chemical resistance ensures longevity in corrosive environments, while thermal stability allows for operation in extreme temperatures. Flexible design absorbs movement and vibration, reducing stress on piping and equipment. Low friction minimizes wear and enhances efficiency. PTFE’s inertness makes it ideal for pharmaceutical and food industries. Versatile configurations suit diverse applications. Overall, PTFE expansion bellows enhance system reliability, longevity, and performance across various industries.