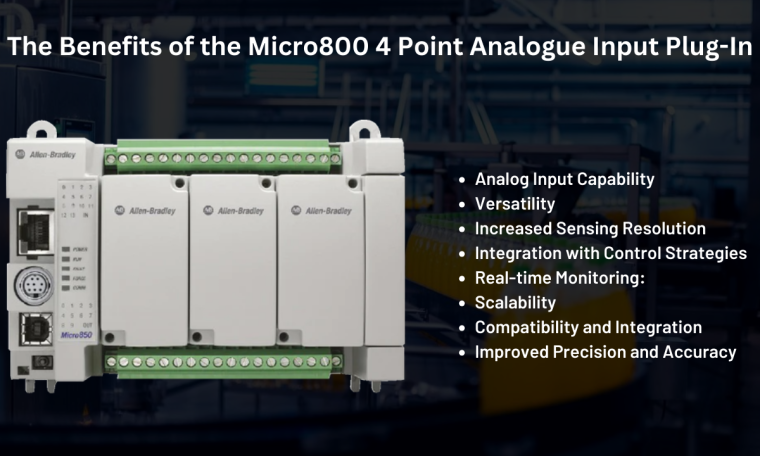

A strong and adaptable tool, the Micro800 4 Point Analog Input Plug-In is made to improve industrial automation and control systems. Numerous advantages provided by this plug-in module help to increase effectiveness, versatility, and performance in a range of applications. Key benefits of the Micro800 4 Point Analog Input Plug-In are listed below:

-

Analog Input Capability:

The PLC can communicate with sensors and devices that output continuous signals, such potentiometers, pressure transducers, and temperature sensors, thanks to analog inputs.

- Continuous Signal Representation: The PLC can receive and interpret signals that vary smoothly over a continuous range thanks to analog input modules. This is essential for tracking and managing physical parameters like as pressure, temperature, flow rates, voltage, and current.

- Voltage or Current Input: Current or voltage are the two most frequent ways to describe analog signals. Analog input modules convert physical measurements into electrical signals for processing by being able to accept inputs within certain voltage or current ranges.

- Resolution: The resolution of analog input modules establishes the lowest discernible alteration in the input signal. More resolution makes it possible to measure and manage the monitored variable more precisely.

-

Versatility:

When managing a range of signals and sensors with varying voltage or current levels, analog input modules offer versatility.

The 4-point arrangement offers versatility in control system design by enabling the simultaneous monitoring of numerous analog signals.

- Increased Sensing Resolution:

When it comes to resolution, analog signals outperform digital signals. Process measurement and control are now possible with greater accuracy because to the higher resolution.

- Reduced Measurement Error: By precisely displaying the true value of the analog signal, the system can reduce measurement errors with higher resolution.

- This is crucial to preserving the accuracy of the data that control algorithms rely on.

- Enhanced Control Accuracy: Accuracy in control systems is crucial. The system can adjust more precisely thanks to higher sensing resolution when it comes to the analog sensors’ response. This helps to improve adherence to setpoints and tighten process control.

- Improved Signal Discrimination: The technology can distinguish between signal levels that are closely spaced apart thanks to increased resolution. This is especially important for situations where even minute changes in the analog input signal have a big impact and need to be recognized in order for the system to react correctly.

Check :- Rockwell Automation 2080-LC50-48QBB Micro820 Programmable Controller

-

Integration with Control Strategies:

Proportional control schemes frequently employ analog inputs. They enable proportionate reactions to modifications in the regulated process as well as more precise adjustments. The 4-point configuration allows for a broader range of input signals to considered in the control strategy.

- Proportional Control: A key component of proportional control schemes are analog inputs. Proportional control adjusts output based on the difference between the current process variable and the desired setpoint.

- Continuous feedback from analog input signals allows for proportionate modifications to be made in order to keep the desired circumstances.

- The total control method utilizes the continuous computation of the integral of the error made possible analog signals from sensors.

- Derivative Control: In derivative control (D), modifications are made based on the error’s rate of change. In order to measure the rate of change and enable the control system to react to abrupt changes or disruptions, analog inputs are essential.

- Analog inputs are crucial for providing complex and efficient control by delivering continuous feedback for derivative, integral, and proportional computations.

-

Real-time Monitoring:

Real-time physical variable monitoring is made possible by analog inputs, which makes control systems more responsive and dynamic.

- Fast Response to Changes: When the environment or process changes, the system can react fast thanks to its analog input capacity.

- This is crucial for applications where maintaining ideal operating conditions requires quick modifications.

- Feedback for Control Systems: Control systems use real-time analog input data as feedback.

- This data enables control algorithms to swiftly adjust output and ensure the process remains within predetermined limits.

- Improved Process Control: Analog input real-time monitoring helps to enhance process control.

- Preventive Maintenance: Analog signal monitoring done on a continuous basis yields useful information for maintenance that is preventive and predictive.

- Analyzing data trends and patterns can help implement proactive maintenance methods, predicting potential equipment failures or issues.

Analog sensors’ continuous feedback makes it possible to comprehend and modify the process conditions more effectively.

-

Scalability:

- Flexibility in System Configuration: Scalability offers flexibility in system configuration according to the particular needs of the industrial process.

- Users can adjust the number and types of analog input modules to suit the application’s specific needs.

- Adaptability to Changing Processes: Scalability makes it possible for the control system to adjust to the frequent changes in industrial operations. Scalable systems are able to adapt to changes in input configurations or the addition of new sensors without causing significant interruptions.

- Multi-System Integration: Scalability encompasses not just the integration of various systems but also the individual components. Coordination of several subsystems is common in industrial automation systems, and scalable designs enable the easy integration of further systems as needed.

- Cost-Effective Expansion: Scalability makes expansion affordable.

- Users can reduce system upgrades costs by gradually adding analog input modules instead of replacing the entire control system at once.

Check :- How Much Java Do I Need to Know Before Learning Selenium?

-

Compatibility and Integration:

Programming environments and the PLC system as a whole easily integrated with analog input modules.

Interoperability with other control system components is ensured by compliance with industry standards.

-

Improved Precision and Accuracy:

Better precision in measuring and regulating variables is provided by analog inputs, which improves the accuracy of the system’s performance as a whole.

Preciseness, adaptability, compact design, smooth integration, scalability, affordability, intuitive configuration, and durability are all features of the Micro800 4 Point Analog Input Plug-In. Because of these advantages, it is a useful part of industrial automation and control systems, improving overall performance and increasing operational efficiency.

Asteam Techno Solutions Pvt. Ltd is a commercial and service company specializing in the comprehensive services for our customers, as well as supply of difficult to obtain industrial automation spare parts. We provide everything that our clients need with reduced time of preparing quotations to the absolute minimum. Due to our extensive expertise working with both local and international suppliers, we are able to provide the highest-quality items at low costs. We specialize in deliveries of the following brands: Allen Bradley, Schneider Electrics, Omron, Siemens, Phoenix Contact, Moxa, Vipa and many more.